Self-Repairing High-Speed Door

Something Completely New: a High-Speed Door That Repairs Itself

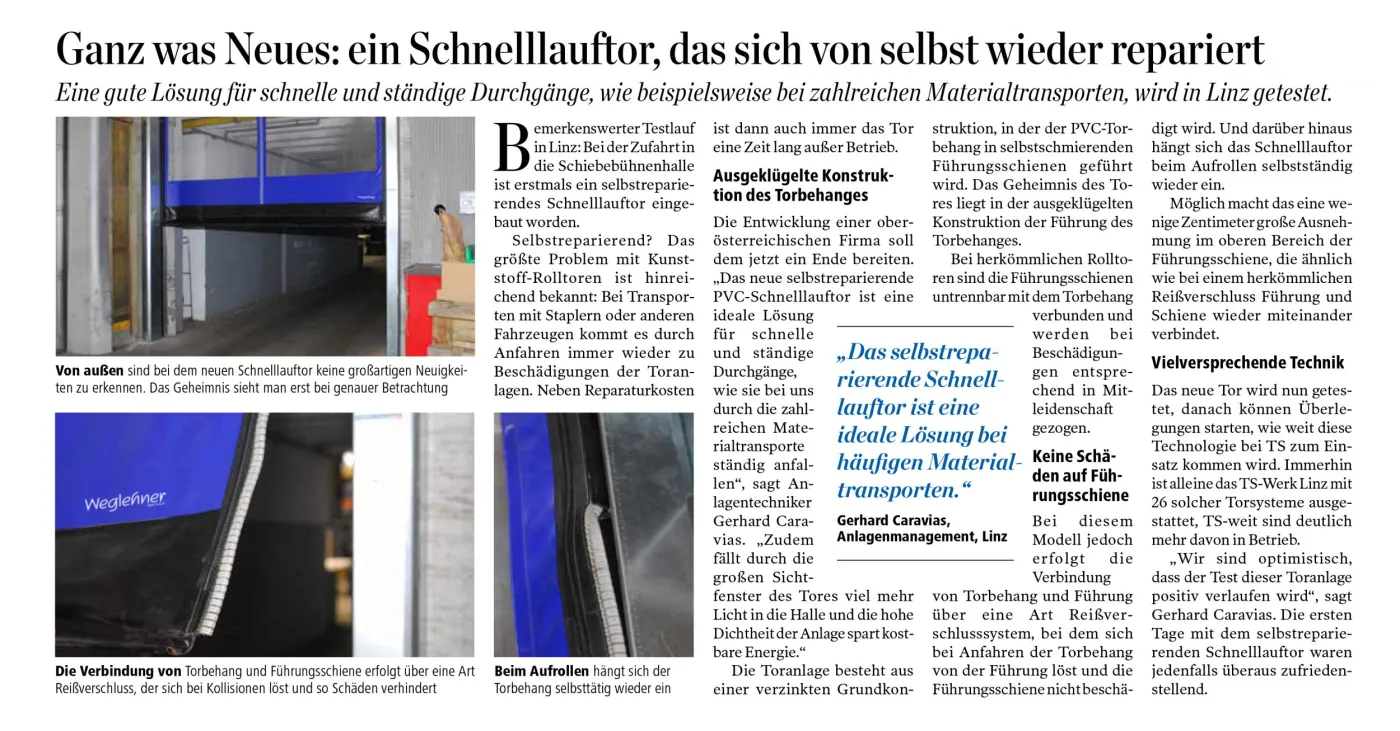

A practical solution for frequent and continuous passage—such as during numerous material transport operations—is currently being tested in Linz. A remarkable field trial is underway in Linz: for the first time, a self-repairing high-speed door has been installed at the entrance to the transfer table hall. Self-repairing? The biggest problem with plastic roller doors is well known: during transport operations with forklifts or other vehicles, the door assemblies are repeatedly damaged due to impacts. In addition to repair costs, the door is also out of service for a period of time. These downtimes disrupt material flow, cause logistical delays, and compromise the building's thermal envelope. As long as the door is damaged, it cannot close tightly, resulting in energy losses.

Sophisticated Design of the Door Panel

A development by an Upper Austrian company aims to put an end to this issue. “The new self-repairing PVC high-speed door is an ideal solution for fast and continuous passage, as we constantly experience with our numerous material transports,” says plant technician Gerhard Caravias. “In addition, the large vision panels in the door allow significantly more daylight into the hall, and the high sealing performance of the system saves valuable energy.” The large vision panels greatly improve natural lighting in the hall, reducing the need for artificial lighting during daytime hours. At the same time, the high airtightness of the closed door prevents heat loss in winter and cold air loss in summer. This directly contributes to lower energy costs and improves the building’s overall energy balance.

The door system consists of a galvanized base frame in which the PVC door panel runs in self-lubricating guide rails. The secret of the door lies in the sophisticated design of the door panel guidance. In conventional roller doors, the guide rails are permanently connected to the door panel and are consequently damaged during impacts. When the door is struck by a vehicle, not only does the flexible PVC panel tear, but often the rigid metal rail is also damaged. This leads to complex repairs, extended downtime, and high costs—for both spare parts and lost production time.

No Damage to Guide Rails

In this model, however, the connection between the door panel and the guide rail is achieved via a zipper-like system. Upon impact, the door panel detaches from the guide, leaving the guide rail undamaged. Moreover, the high-speed door automatically re-engages itself when rolling up. This is made possible by a small recess—just a few centimeters long—at the top of the guide rail, which reconnects the panel and rail similar to a conventional zipper. As soon as the door rises after a collision, the panel automatically slides into this special recess and securely re-locks without any manual intervention. The door is thus fully operational, airtight, and ready for use immediately after the first opening cycle. No repair costs, no maintenance requests, and no operational interruptions occur.

Promising Technology

The new door is now undergoing testing. Afterward, considerations can begin regarding how widely this technology will be deployed across TS. After all, the TS Linz facility alone is equipped with 26 such door systems, and many more are in operation across the entire TS network. “We are optimistic that the test of this door system will yield positive results,” says Gerhard Caravias. The first days with the self-repairing high-speed door have already been highly satisfactory. The technology combines several key advantages: it ensures continuous availability of the loading area, sustainably reduces maintenance costs, improves working conditions through increased daylight, and simultaneously contributes to energy savings. This makes it a forward-looking solution for industrial and logistics environments where reliability, efficiency, and cost-effectiveness must go hand in hand.

PDF download